When it comes to overhead cranes, hoists are an integral part of the lifting process. Without a hoist in place, there is no way for the crane to lift up and down. As such, businesses that rely on industrial cranes need to know about the types of hoists available and the types of lifting mediums they can use with them. In this post, we will cover types of hoists, types of lifting media used by each type, how they work and their operation types, so you can choose what’s best for your needs.

Overhead Hoist Types

There are various types of hoists, each with its own set of features and requirements. Hoists are available in various configurations depending on the lifting media used, the power sources utilized to operate them, and the types of duty they’ll need to perform.

Furthermore, terms describing a specific setup and design often refer to overhead hoist types. The following three areas further define the hoist type:

- Lifting Medium: The lifting medium specifies the component that transmits and generates vertical motion in a hoist load hook or hoist load block.

- Operation: The operation of a hoist determines the type of power used to operate the lifting motion.

- Suspension: The type of hoist suspension is chosen by the way it’s attached to the object or structure. Hook mounted, lug mounted, and trolley mounted are three popular suspension methods. Other forms of suspension may meet specific application demands.

Hoist Lifting Mediums

The types of hoists can be classified by the lifting medium used. The three most common types are:

Welded Link Chain Hoists

Welded link chain hoists utilize a welded-link, carbon steel or stainless-steel lifting medium to transport loads vertically and horizontally via trolleys that slide along railway tracks. This type of hoist is very versatile and can be of use in a wide variety of applications.

A welded link chain is a collection of interconnected formed and welded links. The links fit holes in the load sprocket that transmits motion to the chain. The load sprocket is also known as a load sheave, pocket wheel, or lift wheel.

Welded link load chain sizes are given as the wire diameter of the link, for example, 1/4″, 5/16″. For a specific hoist, welded link load chain is created and sold to meet particular size and strength requirements.

However, the welded link load chain is not replaceable between different hoist manufacturers; and it’s not to be used with welded link lifting chains for other applications, such as chain slings and load securement.

Only a welded link load chain with specifications as initially stated by the hoist manufacturer should be used on any welded link chain hoist.

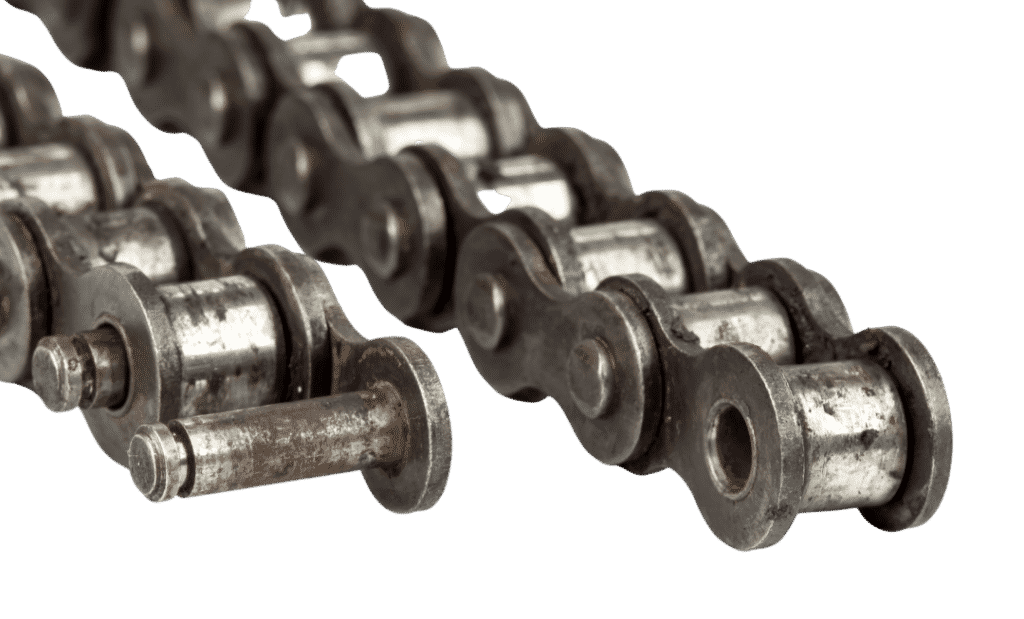

Roller Load Chain Hoists

Roller load chain hoists use a roller-type lifting medium. The chain has cylindrical rollers that fit into the groove of the sprocket, which attach to the crane’s trolley. This type of hoist provides a smooth lift and eliminates any potential for sideloading on hooks or blocks.

The roller load chain is made of a series of alternating roller links and pin links, with the pins moving inside bushings and the rollers free to rotate on them. These pins and bushings are press-fit into the link plates. Thus, the load chain is linked to the hoist load sprocket, which transmits motion to the chain.

.

The hoist roller load chain, as opposed to the power transmission roller chain, has special manufacturing requirements.

As a result, the hoist roller load chain is not interchangeable with the power transmission roller chain. Therefore, any roller load chain hoist should only be used with a roller load chain with the exact specifications as initially stated by the hoist manufacturer.

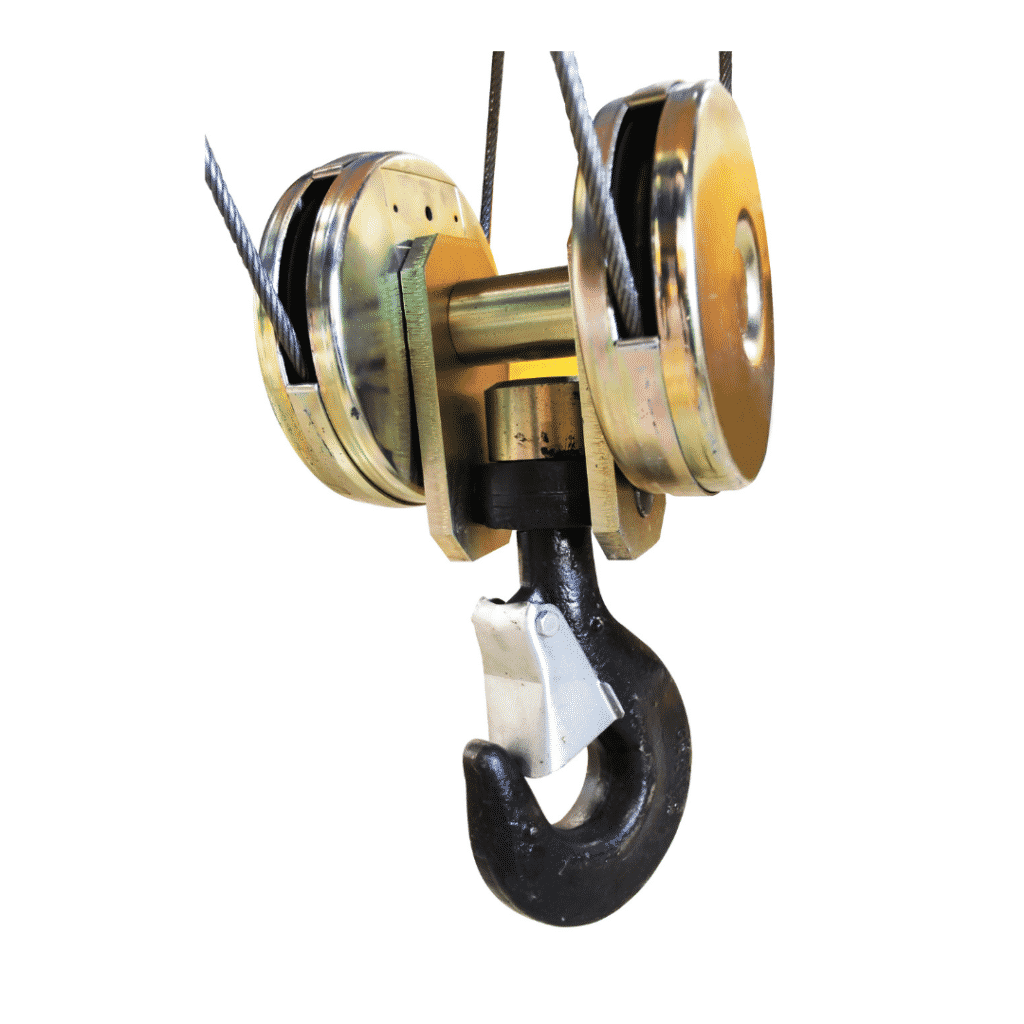

Wire Rope Hoists

Wire ropes are made up of many individual strands and wires laid together in a specific pattern (which varies depending on the application), then they are subject to several processes, such as twisting or wrapping that strengthens and protects it from abrasion. This process creates the hoist wire rope, which then fits the grooves on the hoist drum.

Wire rope is the most common type of hoisting medium and has a wide range of uses. It comes in various types, such as fiber core wire rope, compact stranded wire rope, and parallel-wire strand (PWS) wire rope. These types of wire ropes come with different types of fiber cores, strand construction and number of strands. Each type is fit to a particular hoist application.

The diameter of the wire rope strands is specified as a circle that would enclose the wire rope strands, such as 5/16″ or 3/8″.

However, the hoist manufacturer determines the wire rope’s construction and material strength according to the hoist’s design specification. As a result, wire rope only bearing the manufacturer’s original specifications should be utilized on any wire rope hoist.

Wire rope hoists can lift the most weight. They’re an excellent choice for lifts with extended heights and high capacities that need precise positioning. These hoists may be ideal if the load needs support for lengthy periods. Additionally, a wire rope hoist or winch may lift the burden and satisfy your operational requirements when you require a hoist with a load-bearing capacity of up to 100 tons. These types of hoists are on double girder top running trolley wire rope hoists and double girder under running trolley rope hoists.

Hoist Operation Types

The types of hoist operations are determined by the motion used to lift the load. The most common types are:

Hand Chain Manual Power Hoists

Hand chain manual hoists lift using the operator’s hands, which operate a continuous hand chain supported from the hoist. These types of hoists are good in small spaces and can be easily stopped at any point along the travel.

Manual hoist types do not require electrical or air supply to perform lifting tasks, making them ideal for applications where energy resources may be limited. However, they cannot lift hefty loads and often have a lower capacity than other types of hoists.

Moreover, it comprises a series of interlinking formed or unformed links tailored to the specific requirements of the hand chain. The hoist hand chain wheel or sprocket’s pockets accommodate the links.

The wheel turns as the operator pulls the hand chain, and power is transmitted through the hoist gearing to the hoist load chain sprocket. Pulling in one direction causes the hoist load hook to move in one direction, lifting or lowering the load.

A manual chain hoist comes with welded a link load chain or roller load chain as the lifting medium, and they have a single hand chain. Higher capacity manually operated chain hoists may include additional hand chains connected to the hoist via ropes. Hoists with many hand chains require numerous operators who must grasp and pull one.

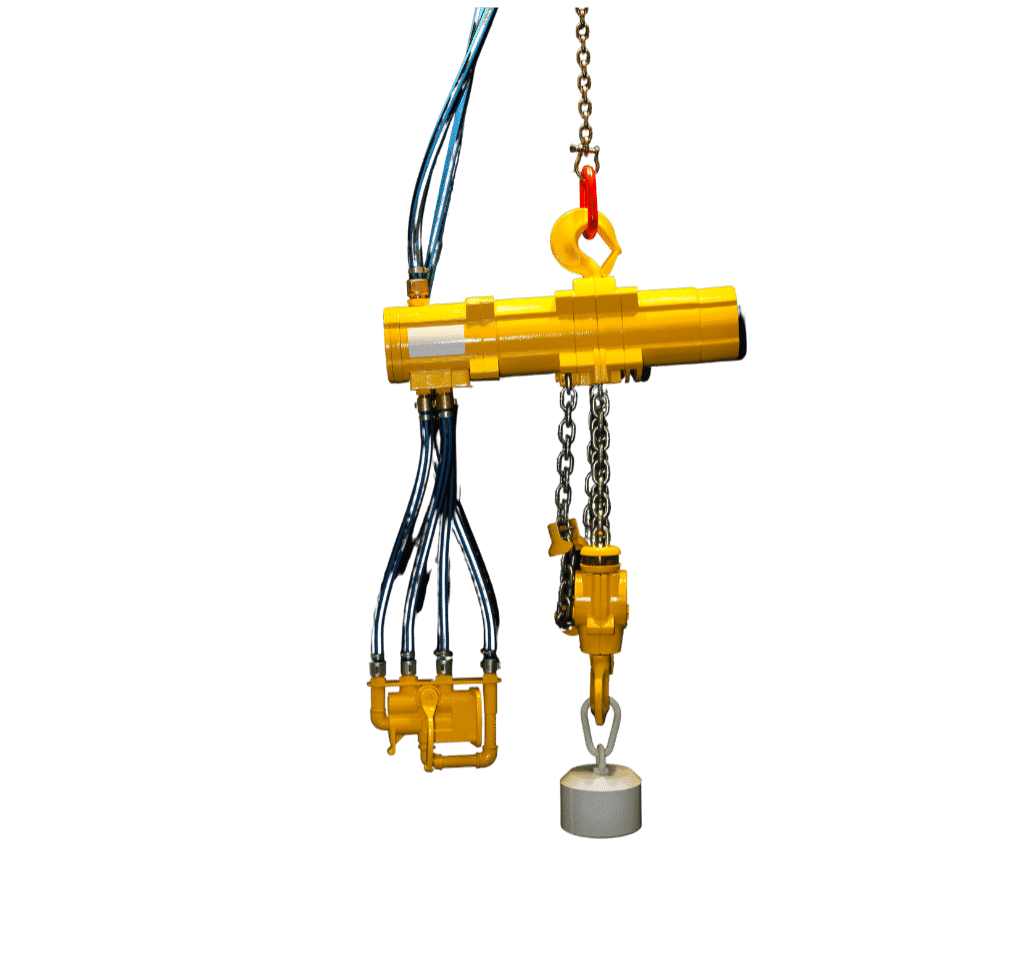

Electric Hoists

An electric chain hoist lifts and lowers materials. The operator activates a control device, which applies electrical power to an electric motor through a chain of contractors and other electrical components. Next, the electric motor transmits power through the hoist gearing to the hoist load chain sprocket or hoist drum, the result being that the hoist load hook is raised or lowered.

The electric hoist lift and lowering controls are actuated in the same manner by manipulating the lifting and lowering handles. The buttons could be labeled:

- LIFT/LOWER;

- UP/DOWN;

- RAISE/LOWER;

- Arrows indicating up and down;

Electric hoist control buttons are typically push buttons installed in a pendant control enclosure suspended from the hoist or levers or switches connected to a remote radio-control transmitter. Additionally, the control device used to lift, and lower hoist motion may also contain other motions or functions.

These controls include:

- trolley travel;

- overhead crane travel;

- power on/off;

- emergency stop;

- motions associated with below-the-hook lifting devices;

- other special functions related to a specific application;

Air Chain Hoists

A pneumatic power or air powered hoist utilizes air pressure to operate the electric motor. Compressed air enables these types of hoists to lift heavy loads up or down at fast speeds. In addition, air powered types of overhead cranes do not require electrical energy, which makes them ideal for applications where electrical energy may be limited.

An air hoist operator must grip and activate a control device to raise or lower themselves. An air motor activates by push buttons or levers on the control device, which sends air through a series of valves and other air components until it reaches the desired level (lifting or lowering). To raise or lower a hoist load hook, the air motor sends power via the hoist gearing to the hoist load chain sprocket or drum.

Lifting is via actuating the lifting control, and lowering is via actualling the lowering control. The controls might be as follows:

- LIFT/LOWER; UP/DOWN;

- RAISE/LOWER;

- Arrows designating up/down.

- Or a combination of such markings;

The controls for raising and lowering the hoist are frequently push buttons or levers in a pendant control housing attached to the hoist or pull controls, which may be located on the building structure or crane cab.

Lever Chain Hoists

Lever chain types of hoists that manually operate. A lever chain hoist is a type of manual lift type that utilizes levers or rods to move the load hook up and down. The operator grasps both sides of the lifting device, which causes it to rotate about its axis as well as raise or lower itself by turning one way or another. A pull on the levers or rods will cause them to rotate about their axis. This action transmits through other components, such as gears and hook types of chains or ropes that attach between these rotating element types of hoist types until it reaches its desired lift position types of cranes.

The lever hoist is similar to a hand chain hoist in that it uses a hand chain to move weight. However, the lever’s reciprocating operation lifts and lowers the low in small quantities. Standard lifts are 10, 15, and 20 feet.

Lever chain hoists have a variety of benefits such as:

- Ideal for construction sites, plant maintenance, and industrial environments

- Design enables the user to pull, lift, and position materials horizontally or vertically.

- Typical lifting capacities range from 1/2-ton to 9-ton

- There’s a 360° rotation of the lever and top swivel hook for simple rigging.

- The lightweight and compact design makes it great for small spaces.

Hoist Suspension Types

Different hoist suspension types lift and lower loads. Hoists have a variety of types that vary due to the type of load being lifted. Common types of hoist suspensions include:

Hook Mounted

The hook mounted hoist may be suspended from the clevis or suspension pin of a trolley, or a permanent suspension device attached to a beam or the structural frame of a structure. Hook mounted crane hoists are often equipped with welded link load chain or roller load chain as the lifting mechanism.

Lug Mounted

Lug mounted hoists have a lug mounting attached to the top of the hoist frame or, more frequently, a lug mounting integral part of the hoist frame. These suspend the hoist from a trolley, a suspension device connected to a beam, or the building’s actual structure.

Trolley Mounted

Trolley mounted hoists are utilized with the overhead crane trolley. They suspend from a fixed suspension device attached to either a beam or structural frame of a building. Additionally, a trolley on the lower flange of a monorail beam or the lower flange of a bridge beam of a crane is sometimes integrated into the hoist frame.

Trolleys & Monorails

The trolley is a device that rides on the crane runway and typically houses the hoist motor, brake, and gearbox. It also has a suspension system to move freely along the beam. The trolley moves the heavy load from one end to the other.

Here are some of the most common types of trolleys:

Plain Trolleys

Plain type trolleys are pulled or pushed by the weight of the load or by some other technique, such as a pendant control straining from the trolley or hoist. These trolleys are preferable when the trolley motion is infrequent or short in duration.

Hand Chain Operated Trolleys

Hand chain manually operated trolleys operate in the same manner as manually operated trolleys, except that they connect by a continuous hand chain that the operator pulls. According to specifications, the design criteria of a hand chain comprise interwoven formed welded or unwelded links. As the hand chain is drawn, the wheel spins and transmits power to the trolley wheels via gearing.

Electric or Air Powered Trolleys

Electric or air-powered trolleys may be pulled by the user grasping and activating a control device in the same manner as electric or air-powered hoists, respectively. Controls for moving a trolley along may also be part of the control device to raise and lower hoist motion. The use of electric powered or air powered trolleys is recommended based on the frequency of usage, distance traveled, load capacity, beam height, and type or size of cargo handled.

Monorail Wire Hoists

The monorail wire hoist is for use with a crane and features an enclosed gearbox. It may be single-speed or multi-speed, depending on the model. Wire rope is fed into the hoist drum, which can reach speeds up to 75 feet per minute.

Hoist Duty Classifications

HMI and ASME has five primary duty classifications for hoists. Each duty cycle category considers several criteria, including the following:

- The average operating time each day;

- Load spectrum;

- Starts per hour;

- Operating periods;

- Equipment life;

Duty classifications are important because they help ensure that the hoist is built for the certain types of applications it is for. For example, a hoist rated for continuous duty will be made with more durable components and won’t fail when run at its maximum load rating 24 hours per day. On the other hand, if you’re using a hoist in an intermittent service application (and there are several types of intermittent service applications), such as moving loads from one workstation to another, you want a hoist that’s rated for intermittent duty.

American Equipment can help you find the right hoist for the job!

If you’re looking for the right hoist for your overhead crane, contact American Equipment today. Our team will help you find the right hoisting equipment by discussing your lift and load requirements. With decades of experience in the industry, American Equipment is the go-to source for overhead hoists. Find your local American Equipment location.