A hoist is a device used for lifting heavy objects. There are many different types of hoists, each designed for a specific purpose. This article will discuss the most common types of hoists and their applications. We will also define some key terminology related to overhead lifting and cranes. If you’re looking to learn more about hoists and how they can help your business, then this is the article for you!

What is a Hoist?

A crane hoist is an overhead lifting device that uses pulleys and cables or chains to move objects. They are usually used on construction sites and in manufacturing plants because they can lift heavy loads safely without much effort required by workers.

Mechanical hoist equipment distributes weight by converting small amounts of force over long distances into greater forces over shorter ones. Hoists have different features such as speed control, multiple lifting speeds, and safety mechanisms like limit switches or load brakes.

What are Hoists Used For?

Hoists are utilized in a wide range of industries, not just those involved with manufacturing. For example, hoists lift freight, building materials, engines, and warehouse goods, among other things.

The following are some common uses of Hoists:

- Construction sites: When it comes to building construction projects, hoists play an essential role. They help transfer heavy loads from the ground level up into place without much effort on behalf of workers.

- Warehouse operations: Warehouse operations require a lot of heavy lifting and moving materials. So, naturally, hoists are used quite often in these situations.

- Manufacturing line tasks: In manufacturing lines, hoist mechanisms transport raw materials or completed products between different stages along the assembly process. These processes require precise movement at the right time and location. Thi means they must be operated by skilled workers who can accurately handle complex tasks.

Overall, there are many different types of hoists for all sorts of applications. Each type has its advantages and disadvantages, so it’s important to do your research.

Read More: What are the Different Types of Hoists for Overhead Cranes?

How Do Hoists Work?

Hoists work by transferring the load from the hook to the traveling beam. The power unit, which is usually located at one end of the beam, provides the lifting or lowering motion. The operator stands on a platform near the other end of the beam’s other end and controls its movement.

Some hoists have an automatic overload protection device that decreases the lifting speed as the load approaches its maximum capacity. If the load exceeds this capacity, the device will stop the hoist from lifting. This prevents damage to both the load and the equipment.

There are many different types of hoists, each with its unique features and applications. It can be challenging to choose what will work best for your industrial overhead crane and hoist system needs with so many options available.

What are the Different Types of Hoist Lifting Systems, Mediums, and Suspension?

There are various types of hoisting equipment within these three categories, which have unique features and applications. First, we’ll go over the lifting systems most commonly used in industrial applications.

Electric Wire Rope Hoist: Electric wire rope hoists are the most common type of hoist used. They use an electric motor to power the lifting motion. Additionally, they come with a variety of features such as multiple speeds and safety mechanisms.

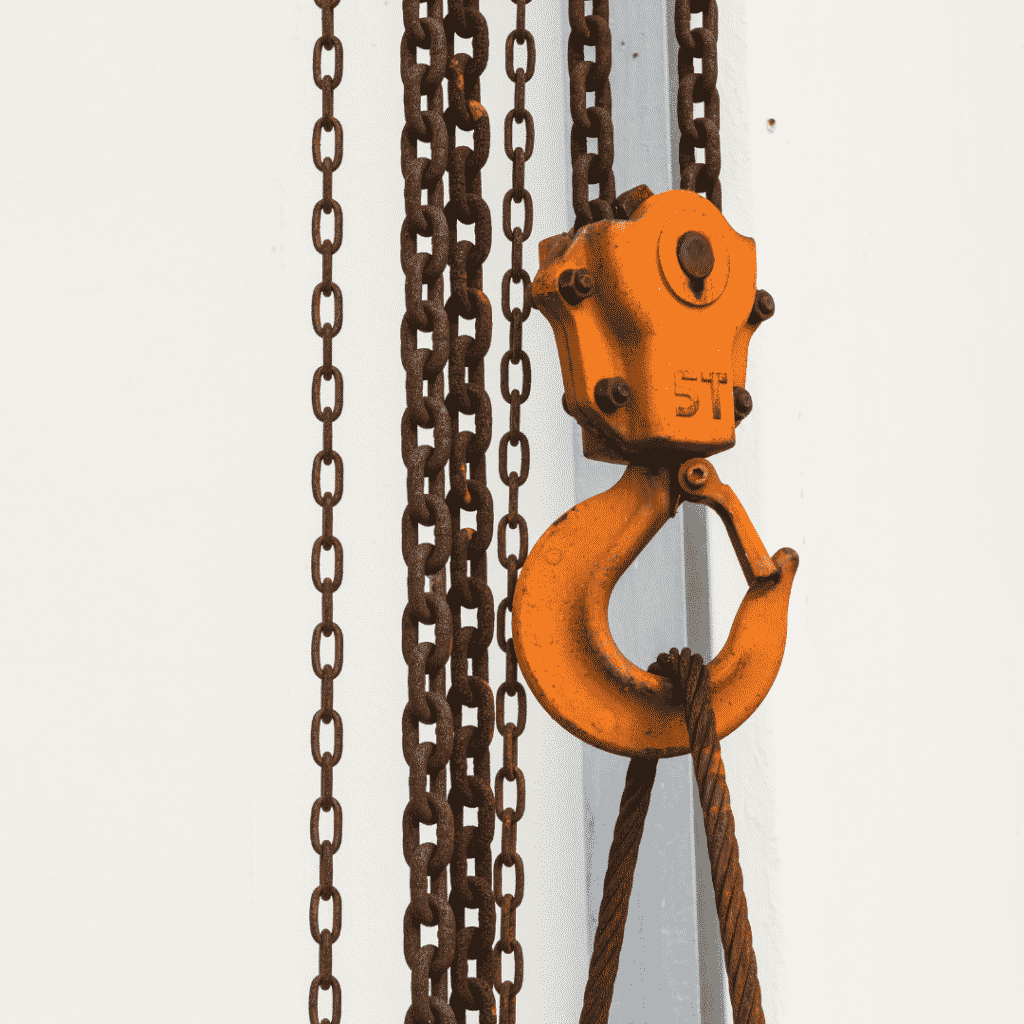

Chain Hoist: Chain hoists are similar to electric wire rope hoists, but they use a chain instead of cables to move the load. They’re often used in manufacturing plants because they can handle more weight and have a lower cost than other types of hoists.

Pneumatic / Air-powered Hoist: Pneumatic hoists use compressed air to power the lifting motion. They’re often used in tight spaces where electric or chain hoists can’t fit, and they come with various features such as adjustable speeds and overload protection devices.

Manual Hoist: Manual hoists are operated by hand and are best suited for light-duty applications. They’re often used in construction or manufacturing settings when a power source is not readily available.

The type of system that’s best for your industrial overhead crane and hoists needs will depend on what you’re trying to raise or move. Along with the type of hoist, there are also different types of lifting system suspensions.

Suspension Types

Hook mounted: Hook mounted is a type of system where the hoist is attached to crane hooks. This system is widely used in manufacturing and transportation applications.

Trolley Mounted: Trolley mounted suspensions are similar to hook mounts, but they’re more often used in applications where loads need to be moved horizontally as well as vertically. The lifting medium (or what’s being lifted) is attached to a carriage that rides on a track. This system is often used in conjunction with electric or chain hoists.

Lug mounted: Lug mounted suspensions are used to lift loads that are too large or heavy for trolley mounted systems. The lifting medium is attached directly to the suspension system, which then hangs from the crane hooks.

There are also a variety of different hoist suspension types within these three categories. To find what will work best for your needs, it’s important to consider the weight and size of the load you’re trying to lift, as well as the space restrictions of your work area.

Lifting Medium Types

There are a few different types of lifting mediums that can be used with hoists. The type you choose will depend on what your needs are and what materials the crane will lift most often.

Wire Rope: Wire rope is made up of strands wrapped around a central core, making it strong enough to handle heavy loads without breaking. It’s often used in cranes and other overhead lifting systems because it’s durable and can be easily customized to fit the needs of your application. Read More.

Welded Link Load Chain: Welded link load chains are made from links that have been welded together to create a continuous loop. They’re used in manual hoists because they don’t require any maintenance and can be easily adjusted as needed without tools or equipment.

Roller Load Chain: Roller load chains consist of small rollers that help to distribute the weight of the load evenly. This prevents damage to the chain and makes it easier to handle heavy loads. They’re often in pneumatic hoists because they can handle more weight without breaking.

Now that we’ve gone over the different types of lifting systems and medium types, let’s take a look at some of the features that are common to all hoists.

Features of All Hoists

Regardless of what type of hoist you choose, there are a few features that are common to all models. These include:

- Lifting Capacity: This is the maximum weight the hoist can raise without breaking. It’s important to choose a hoist with enough lifting capacity for what you need it to do.

- Lift Speed: This is how fast the hoist can raise or lower its load. Different types of hoists will have different speeds, so make sure you know what your needs before purchasing one that isn’t suitable for your application.

- Lift Height: The lift height is how high the hoist can raise its load. This will vary by manufacturer, so make sure you know what your needs are before purchasing one that isn’t suitable for your application.

- Lift Material: This is what the hoist will be lifting. This can be either a solid material like steel or concrete, or it can be a liquid or gas.

- Power Source: This is what powers the hoist. Most hoists are either electric or pneumatic, but there are a few manual models available as well.

- Suspension Type: This is what the hoist will be suspended from. Most hoists are either hook mounted, trolley mounted, or lug mounted, but there are a few other options available as well.

- Headroom: This is the amount of space above the hoist that’s needed to operate it. Make sure you have enough headroom before purchasing a hoist that won’t fit in your work area.

What To Consider When Choosing a Hoist

With so many different types of hoists available, it’s important to choose what will work best for your needs. Here are a few things to consider when choosing the right one:

- Lifting capacity: This is how much weight the hoist can raise without breaking. Different types of hoists will have different capacities, so make sure you know what your needs before purchasing one that isn’t suitable for your application.

- Travel distance: This is how far the hoist needs to travel in order for it to perform its task. If the distance is too far, it may not be able to lift the weight you need it to.

- Ease of use: A hoist that’s easy to use will make things much more manageable, especially if you’re not used to using one regularly. It might be worth investing in some extra training or reading up on what type of equipment will best suit your needs before making a purchase decision.

- Safety features: Make sure the hoist has all necessary safety features and is well-maintained so that it doesn’t break down while on the job site. Consider having a crane safety checklist to keep on hand so you can be sure the hoist is up to par.

- Operating time and usage: How often is the hoist going to be used? How long will it need to run each time? These are important factors to consider when making your purchase, as some hoists require more frequent maintenance than others.

- New vs. Old hoist: If you’re looking for a replacement hoist, it’s important to know the difference between new and old models. New hoists typically come with more features and are easier to use, while old hoists may be less expensive but require more maintenance.

- Crane and hoist operator: If you’re not familiar with how to operate a crane or hoist, it’s important to find someone who is. Make sure they are certified and know what they’re doing before handing over control of your equipment.

Once you are familiar with all the moving parts and what to look for in a hoist, you’re ready to make your purchase.

Read More: Before You Lift: 6 Top Safety Tips for Crane Operation

Need an Overhead Crane Hoist Solution? (Contact American Equipment)

When it comes to heavy lifting, it’s important to know the terminology. By understanding the basics of what a hoist is and how it works, you’ll be better equipped to make informed decisions about your industrial overhead crane and hoist system needs.

American Equipment has been providing quality overhead crane and hoist solutions for decades. We offer a wide range of overhead crane and hoist products and services, so we’re sure to have what you need to get the job done safely and efficiently.

Contact us today for more information or to discuss your specific needs with one of our certified crane specialists. We’ll help you find the right overhead hoist solution for your business and make sure you’re up and running in no time.