What is a Bridge Crane? – Bridge Crane Types, Uses, and Pros & Cons

If you’re in the market for a bridge crane, it’s important to understand exactly what they are capable of, how they work, and the different types that are available. In this article, we’ll go over what a bridge crane is, bridge crane types, and the pros and cons of each type. We’ll also give you […]

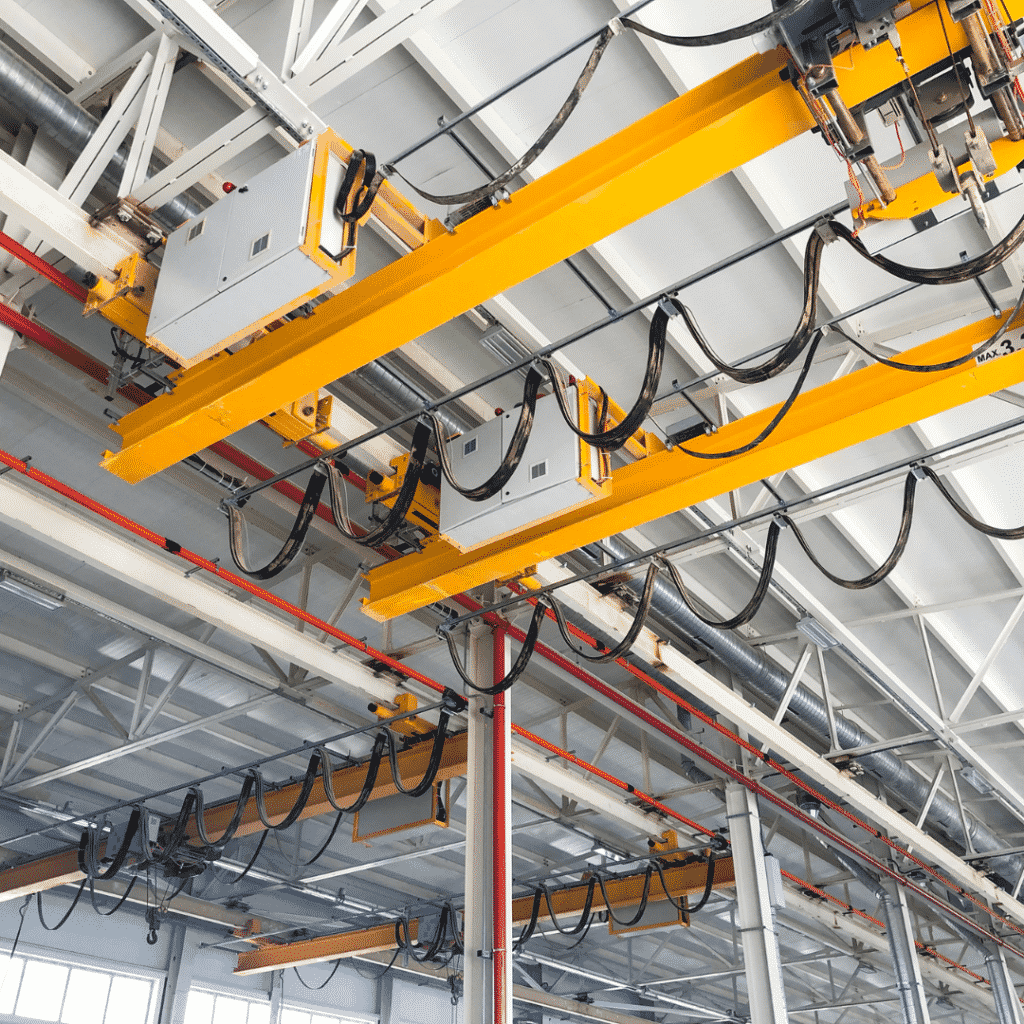

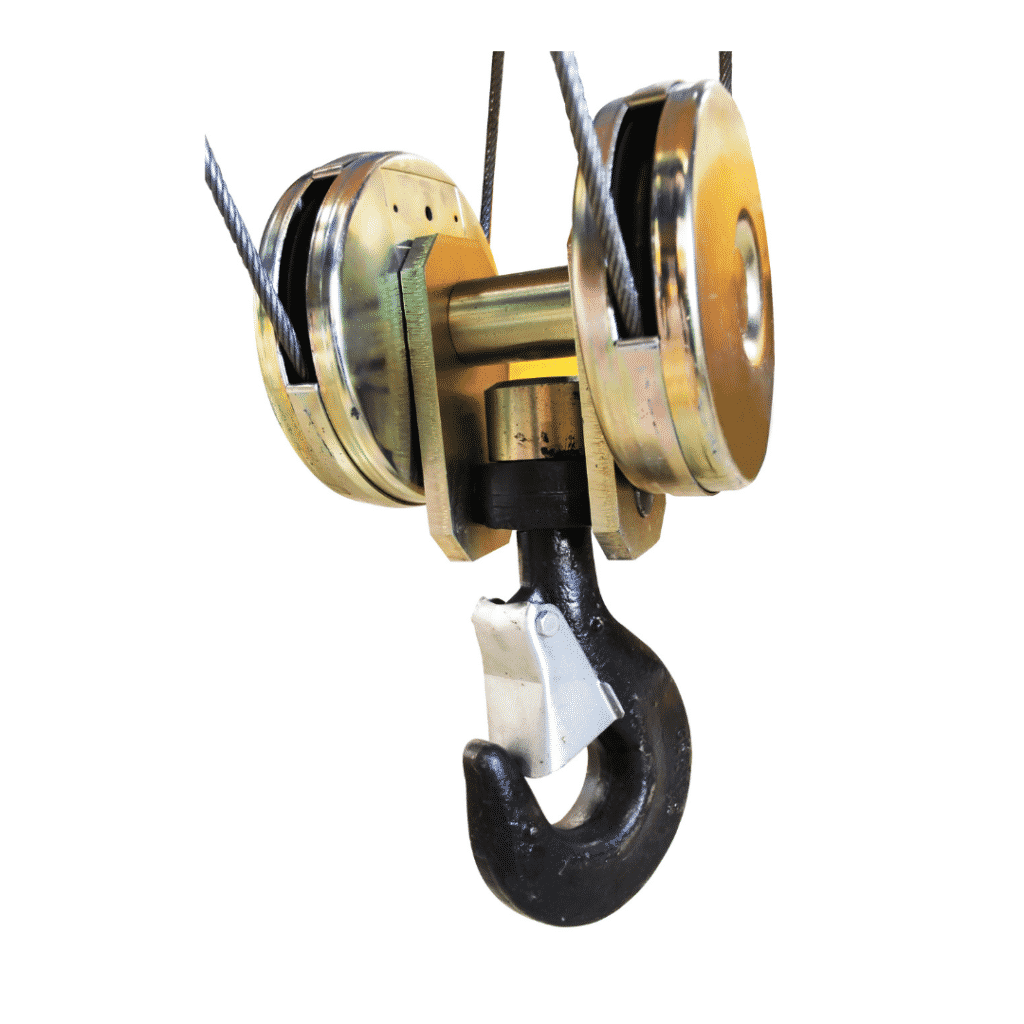

What is a Hoist?: Overhead Lifting & Crane Terminology

A hoist is a device used for lifting heavy objects. There are many different types of hoists, each designed for a specific purpose. This article will discuss the most common types of hoists and their applications. We will also define some key terminology related to overhead lifting and cranes. If you’re looking to learn more […]

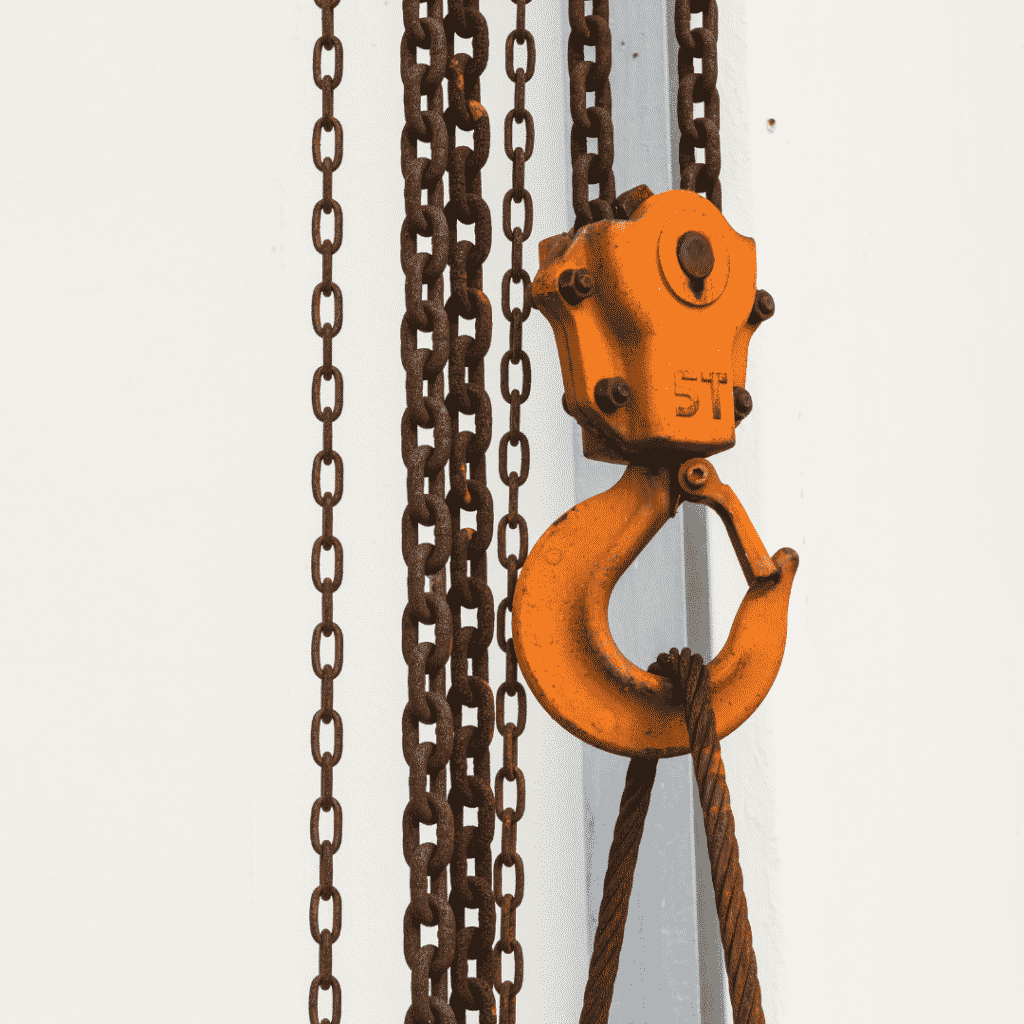

What is Wire Rope?: Types, Specifications, and Overhead Crane Applications

As crane experts, we often get the question “what is wire rope?” Many people know that they need it for their lifting application, but don’t know what to ask for when they go to purchase it. Our aim is to provide you with the information you need to feel confident in your purchase and understand […]

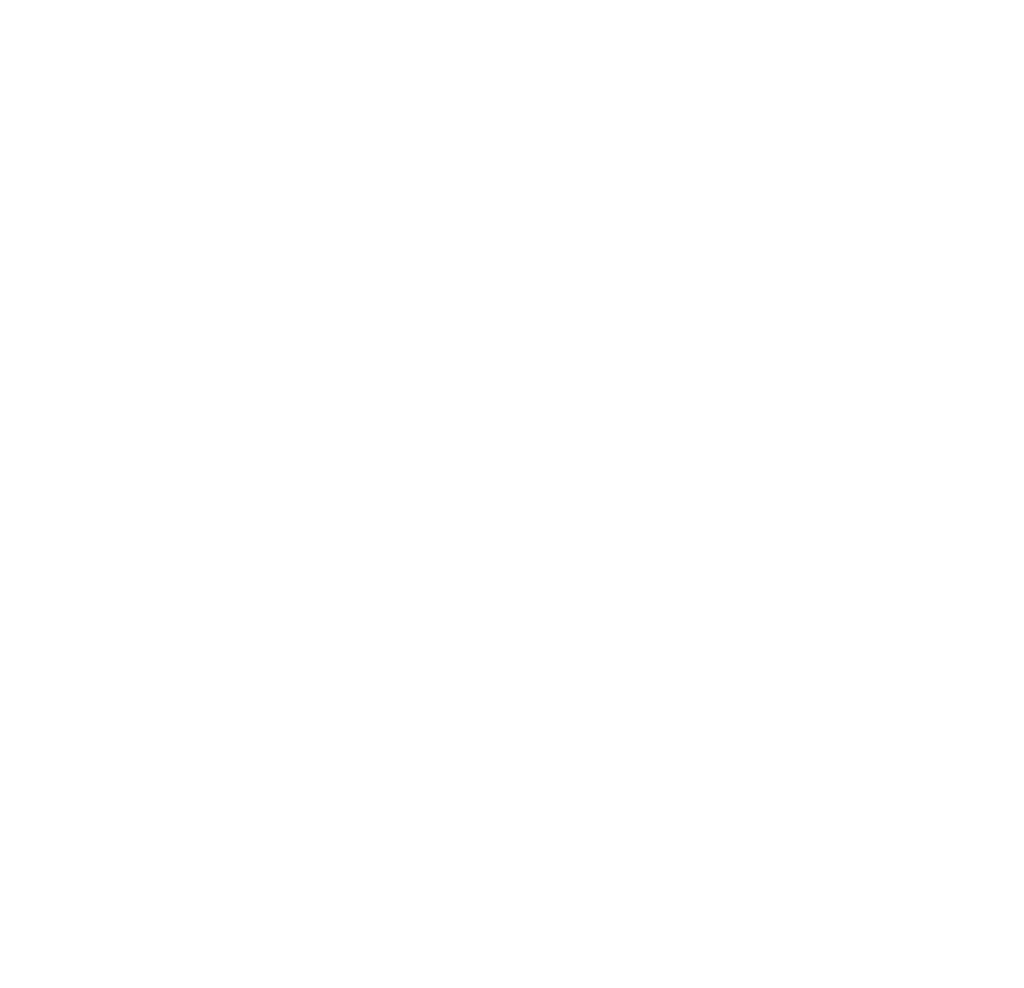

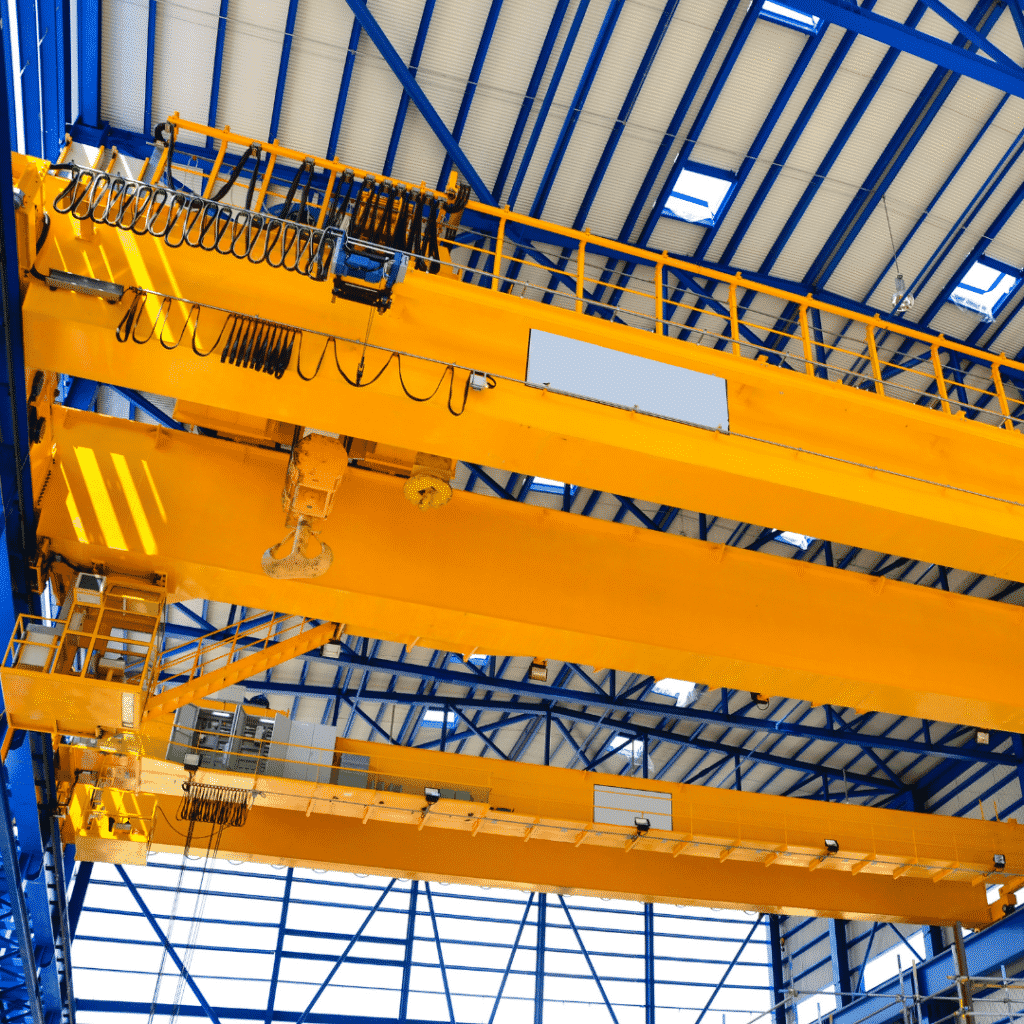

What is an Overhead Crane?: Types, Components, and Terminology

An overhead crane is a lifting device that can move, assemble, position, and handle heavy objects. This article will introduce what you need to know about overhead cranes before purchasing one. Moreover, it will also discuss crane components within the system and what types of applications they are typically for. What is an Overhead Crane? […]

What are the Different Types of Hoists for Overhead Cranes

When it comes to overhead cranes, hoists are an integral part of the lifting process. Without a hoist in place, there is no way for the crane to lift up and down. As such, businesses that rely on industrial cranes need to know about the types of hoists available and the types of lifting mediums they can […]

Overhead Crane Types

It is no surprise that overhead cranes are for lifting material overhead, but there are many different types. It can be confusing to understand the overhead crane types and what they should choose based on their needs. In this article, we will outline the three most common overhead crane types. We’ll also explore what business owners should consider when […]

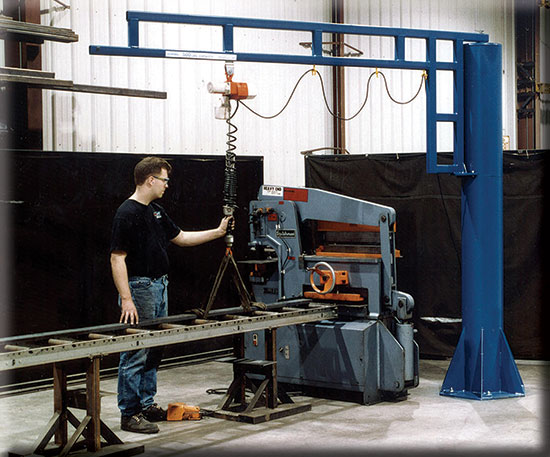

What is a Jib Crane?

A jib crane is a type of crane that typically spans between two points and can move heavy objects. Jib cranes come in various sizes and shapes. Most commonly they are seen as an A-frame structure with a one-arm extension at an angle from the main beam. These cranes are of use for moving large pieces of machinery […]

What is a Gantry Crane?

At its most basic level, a gantry crane is a machine that can move heavy objects. It moves these objects by suspending them from cables and pulleys which attach to an overhead rail. There are many different types of cranes, but the primary purpose is always the same: lifting heavy loads for construction and manufacturing […]

The Basics of Ergonomics for Overhead Cranes

As a business owner, you often think of your industry in terms of the big picture. You must create professional networks, meet industry standards and plan for the future of your business. However, no matter how large your endeavor becomes, you must also be aware of small details that can have a large impact. One […]

Operating an Overhead Crane in Extreme Weather

As an overhead crane operator, you’re dealing with a powerful machine that can lift more than 30,000 pounds. But you’re also dealing with a dangerous piece of equipment that could cause serious problems if something goes wrong. Your experience and training can help you prevent everyday crane problems. But are you prepared to handle abnormal […]