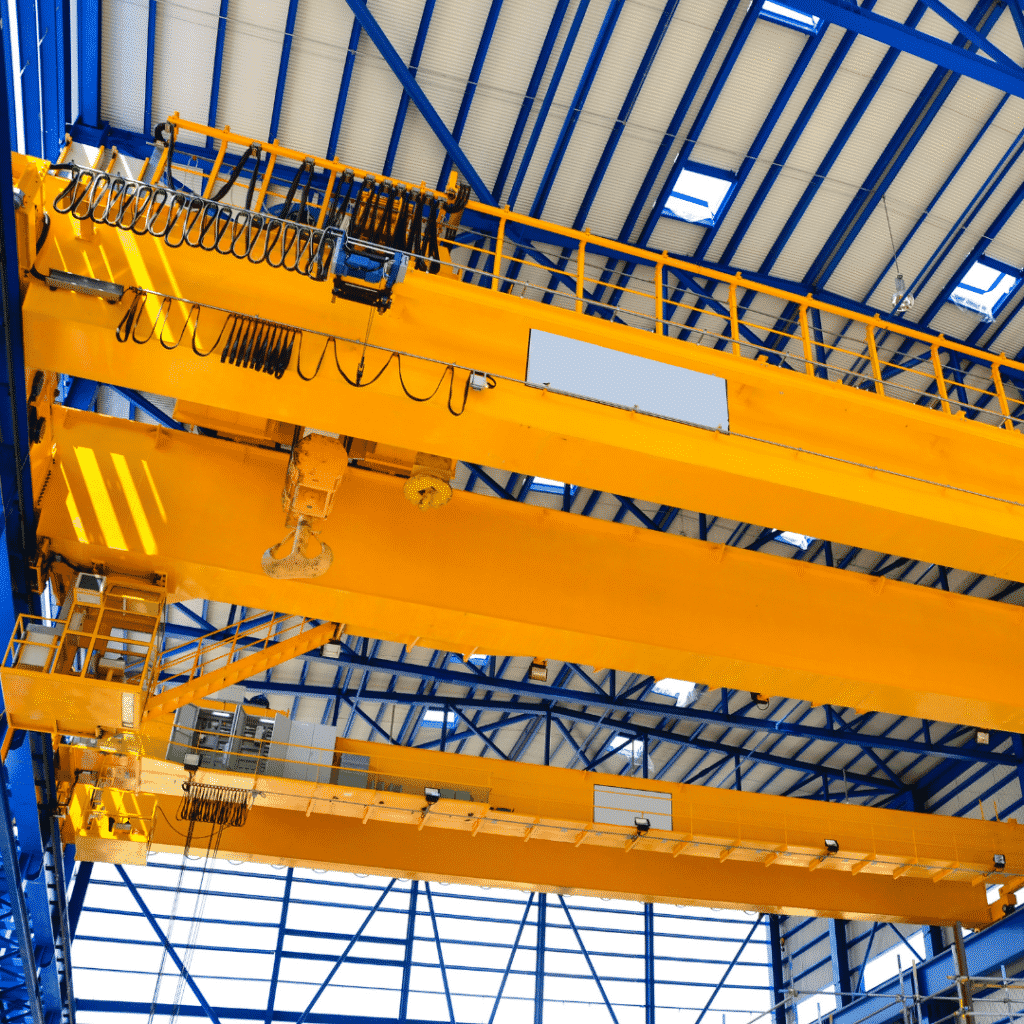

An overhead crane is a lifting device that can move, assemble, position, and handle heavy objects.

This article will introduce what you need to know about overhead cranes before purchasing one. Moreover, it will also discuss crane components within the system and what types of applications they are typically for.

What is an Overhead Crane?

Heavy lifting is what overhead cranes do best.

Simply put, an overhead crane is a machine that moves a load horizontally across the ceiling of a facility rather than down corridors or on the floor. Overhead cranes have significant lifting power for material transport. The operator uses manual controls or a wired pendant station to control the crane’s motion. The most frequent applications are multi-directional movement of materials for industrial storage, and loading or unloading activities within a facility, yard, railway station or port.

Importantly, overhead cranes are available in various sizes, shapes, and configurations with attachments and add-ons.

Efficiency and safety are the two most common reasons for employing an overhead crane. Overhead cranes can complete operations in a fraction of the time it takes other types of equipment. Thus, these types of cranes can lift and move far heavier loads than floor or ground-based machines. Additionally, they may remove materials without endangering people in hazardous, dangerous, or severe environments with heated metals, chemicals, or toxic materials.

How Does an Overhead Crane Work?

Overhead cranes move a load across a rectangular area from side to side and backward and forward.

A trolley with the lifting equipment, known as a hoist, hauls horizontally across a bridge beam linked to one or more horizontal girders supported at either end-by-end trucks. The end trucks connect at right angles to the girders and travel on fixed runways.

An overhead crane operator using a pendant station or wireless control controls the travel and speed of the crane.

Overhead Crane Components

However, although not every overhead crane is the same, they all have specific essential components such as a hoist, trolley, beams, girders, and controllers.

Bridge Beam

The bridge beam is the main horizontal beam that the trolley moves across. It is usually made of steel and can be customized to fit the application’s specific needs.

Girders

Girders support the bridge beam and connect it to the end trucks. They come in various shapes and sizes depending on the load capacity needed for the application.

End Truck

The end trucks are what support and move along the facility’s runways. They can be powered or non-powered depending on what is best suited to your needs. Additionally, some cranes also come with rotatable truck options that allow for more versatility. Thus, providing movement across different floors, surfaces, and even terrain.

Hoist

The hoist carries the load attached to a hook or fork at its end. The hoist may have an electric power motor, hydraulics, pneumatics, or gravity, depending on what type of crane you have purchased and what power source best fits your needs.

Chain and wire are the two most popular hoists for an overhead crane. A chain hoist is held in place by a chain holder and lifts weights less than ten tons. Therefore, they give genuine vertical lift and rise straight up without any lateral movement.

Wire rope hoists raise loads up to ten tons or more. However, they provide a lot more possibilities and adaptability. A wire rope hoist, unlike chain hoists, is susceptible to lateral movement.

Read More: What is a Hoist?

Lifting Trolley

The lifting trolley is what the operator uses to control how far and what direction the load will travel. It can adjust side to side, up and down, or in various angled directions depending on what specific applications need.

The device includes a mechanism that consists of a brake, motor, reducer, drum, and set of pulleys. The motor powers a drum that turns through the reducer to power the wire rope or chain that lifts and lowers the weight.

Driving Mechanism

The driving mechanism moves the lifting trolley back and forth across the bridge beam. It can be a hydraulic drive, servo motor drive, or another type of power source, depending on what best fits your needs.

The driving mechanism of a crane comprises two elements. The long transmission that drives the wheels on both sides is coupled with a separate motor that drives each set of wheels.

Power Supply

What keeps the overhead crane moving is its power supply. There are numerous sorts of power supplies with multiple connections for each one. Conductor bars, festoon systems, and cable reels are the three most frequent types.

Generally, most overhead cranes run on electrical power, although there are pneumatic-power versions. The cable festoons, conductor bars, or reel cables transmit electricity to the crane runway and bridge crane control. This energy supply operates the trolley and hoist.

Height

The type of motor and the crane’s lifting capacity is determined by the height it is put in. The lift height for an overhead crane refers to the distance from the floor to the saddle of the hook, which is a crucial measurement since it ensures there is enough lift space and room to re-position the load.

Controls

The operator has complete control of the load via overhead crane controls. The most basic type of controls features a start and stop button, whereas more advanced controls feature joysticks and tablets to allow for more complex movements and motions.

Overall, the overhead crane consists of many different parts that work together to provide a heavy lifting solution for your facility. Understanding what each part does and its purpose makes it easier to understand how the overhead crane works as a whole.

Overhead Crane Types & Applications

Cranes come in a variety of styles and are compatible with several attachments to facilitate load lift, including:

- Single girder crane – The bridge beam is a single girder that runs on the bottom flange of the main arm. It’s an overhead traveling crane with one bridge beam linked to the two runway/end trucks. A lifting device or hoist travels along the base flange of the bridge beam.

- Double girder crane – Two bridge beams are on top of the runway end trucks in these cranes. Typically, top running cranes come with a top running trolley hoist that travels on its own set of wheels along the top of the two bridge beams.

- Gantry crane – The gantry crane has four legs supporting and moving it. The feet connect to the legs. The legs move along rails to place the bridge for loading, raising, and transporting.

- Overhead bridge crane – An overhead bridge crane has two runways built into the sides of a structure and connected to the superstructure. The runways join by end trucks that move on the runway’s wheels. A single or double bridge may have a trolley moving along each. The trolley and hoist are underhung and travel along the bottom of the structure.

- Monorail crane — Monorail cranes do not use a bridge or girders. The trolley connects to an I beam in the ceiling that travels along the flat surface at the bottom of the beam. Material flows straight down the beam.

- Jib crane – A jib crane is a form of overhead crane that does not require a bridge, runway, or other type of track system.

- Workstation crane – A workstation crane is primarily for material movement within a limited space.

Ultimately, depending on the type of overhead crane you need, what the load is, and the space limitations in your facility, there may be more than one solution.

Read More: Overhead Crane Types

Overhead crane terminology to know

- Axial load — A compressive force directed in the direction of a beam’s axis.

- Box section — A steel beam or bar in the shape of a box used to create beams, struts, and other structural components.

- Drag brake — A brake attached to the trolley or bridge that resists the forward motion of the load, used to control speed, and stop the load.

- Explosion-proof — A type of overhead crane that is safe for use in an explosive environment.

- Lifting capacity — The maximum weight that an overhead crane can lift.

- Lifting speed — The speed at which the load will be raised or lowered.

- Running speed — The speed at which the overhead crane moves.

- Span — The horizontal distance between the end trucks or runways.

- Wheel load — The weight of the overhead crane itself plus the trolley, hoist, and load.

How are overhead cranes used?

Overhead cranes move heavy loads in factories, warehouses, and other industrial settings. Cranes can transport goods between different areas or load and unload trucks.

Common examples of crane applications include:

- Assembly;

- Transportation;

- Warehousing;

- Loading and unloading;

- Packaging;

Common examples of industries that use overhead cranes are:

Manufacturing: cranes move parts throughout the facility, from one department to another, and onto assembly lines for final assembly or packaging.

Construction: overhead cranes can transport heavy materials such as steel beams between floors during construction. They may also place heavy equipment in specific locations.

Steel mills: cranes move heavy materials such as molten metal.

Logistics and distribution: lightweight items can be moved by hand, but larger or bulkier loads require overhead crane systems for material handling.

Biomass plants: cranes move heavy wood and other materials.

Mining operations: overhead cranes transport ore, coal, or gravel from one area of the mine to another and transport mining equipment.

Food processing plants: during food preparation, large quantities of ingredients must move through a plant’s facility, so many food processing plants have overhead cranes.

Gas & Petroleum: overhead cranes transport products and equipment between different areas in a refinery or gas plant.

Beverage plants: overhead cranes move heavy cartons of finished products.

Automotive plants: overhead cranes transport materials and supplies.

Overall, many businesses choose overhead cranes because they offer numerous benefits, including high productivity, reduced labor costs, and increased safety.

Contact American Equipment for help with an overhead crane for your business.

If you are unsure what type of overhead crane and hoist equipment you need, our team can help you determine the best solution for your specific application. We also offer installation, service, and parts for all types of overhead cranes. Contact us today to learn more.