If you’re in the market for a bridge crane, it’s important to understand exactly what they are capable of, how they work, and the different types that are available. In this article, we’ll go over what a bridge crane is, bridge crane types, and the pros and cons of each type. We’ll also give you a few tips on how to choose the right bridge crane for your business.

What is a Bridge Crane?

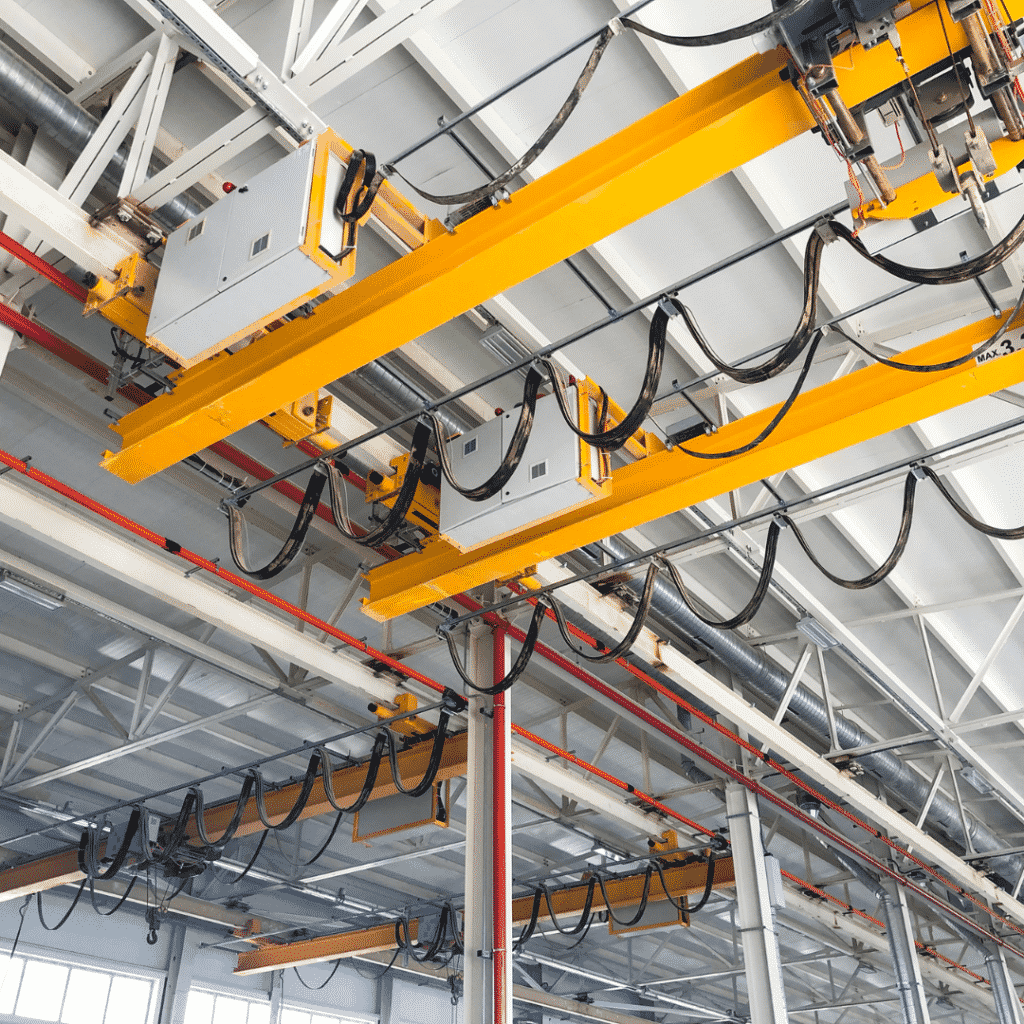

A bridge crane, sometimes called an overhead bridge crane, is a type of non-mobile crane supported by a beam with a movable bridge that travels on beams suspended from overhead. This enables a load to be moved in three axes across any point within the crane’s operating space, meaning it can move left and right, up and down, as well as across the floor.

Overhead bridge cranes are heavy-duty material handling equipment with high loading capacities. An operator steers a bridge crane manually or uses a wired pendant station or wireless controls. Bridge cranes are typically used for multi-directional material transport to help manufacturing, storing, loading, and unloading operations in an industrial facility.

Bridge cranes offer a wider range of motion and more flexibility than other overhead cranes. This makes them ideal for moving large or heavy loads in multiple directions, which can be especially helpful in manufacturing facilities where products are often transported between different workstations. Bridge cranes can also be used to load and unload trucks, making them an essential part of any supply chain.

How Does a Bridge Crane Work?

Understanding how a bridge crane works is essential to knowing how to use one safely and effectively. Bridge cranes use a trolley to move the bridge along the beam. The trolley is attached to the bridge and rides on steel wheels that run in grooves on the underside of the beam. The crane’s hoist is mounted to the trolley and can be used to lift or lower loads.

The bridge of the crane extends longitudinally along both tracks laid on both sides of the runway beams, and the trolley of the crane runs transversely across it, forming a rectangular working area where things can be lifted without being restricted by ground equipment.

Bridge Crane Components

A bridge crane typically has four main components:

- The crane bridge – travels along the runway beams. The bridge travels on an overhead runway system consisting of two parallel runways. The crane bridge has wheels or trolleys that move along the top flange of each runway beam. There are at least two bridge girders that make up the bridge of a crane and support the trolley and hoist.

- The trolley – travels along the bridge. The trolley is mounted on the bridge and can move along both directions of travel. A trolley has wheels or rollers that allow it to move on a bridge girder.

- The hoist unit – moves vertically in the trolley, lifting and lowering loads by means of a chain or rope mechanism connected to its hook.

- The runway – a pair of I-beams or H-beams that the bridge and trolley travel on.

Each part of the bridge crane works together to move loads. The hoist lifts and lowers materials, while the trolley moves across the bridge, left or right.

The trolley is what transports heavy material along a rail at overhead heights; it can be controlled via radio frequency remote control, pendant controls, or while in a cabin attached to the crane.

Bridge Crane Terminology

The following is a list of terms used to describe and differentiate the various types of bridge cranes.

- Crane capacity: The maximum weight the bridge crane is permitted to lift.

- Crane span: The distance between the rails on the runway that the crane travels.

- Lift or hook height: The distance between the floor and the crane hook is what determines how high the runway is from the floor. This distance is also affected by how tall the building is inside.

- Bridge, trolley, and lift speeds: The rate at which the bridge or trolley runs can be set to two different speeds.

- Crane bridge: The basic traveling element of a bridge crane, which is made up of two end trucks and one or two bridged girders depending on the type of crane.

- End trucks: The bridge crane has two trucks on either side of the span. The end trucks have the wheels that the crane runs on.

- Bridge girder(s): The bridge girder is the main horizontal beam on the crane bridge. This beam is supported by the end trucks. The bridge girder is also used to support the trolley.

- Trolley hoist: The trolley hoist is made up of a hoist and a trolley frame. Depending on what needs to be lifted, one or more hoists can be installed on the trolley frame. The hoists can be supplied on the same trolley or on separate trolleys.

- Trolley: The trolley takes the hoist across the bay on a bridge. The bridge has girder(s) that the hoist goes across.

- Hoist: The main lifting equipment for a crane is the hoist. The hoist is mounted to the trolley and together they can lift heavy objects.

Types of Bridge Cranes

There are a few different types of bridge cranes based on different factors, such as the number of hoists and how they work.

- The most common type of bridge crane is a single girder overhead or under running crane with one lifting device (hoist). It has two end trucks that run along a pair of rails that are installed on two runway beams. The trolley moves along the bridge and is used to transport material. The bridge has a capacity of up to 50 tons.

- A double girder crane is the same as an overhead crane but with two bridges (girders) and two trolleys. This type of crane can handle heavier loads, up to 100 tons. It also requires more space than the single girder crane.

- A top running bridge crane is used to lift and move heavy material, and the trolley travels right underneath the bridge. This type of crane is more expensive than an overhead crane but offers greater lifting capacity.

- An under running bridge crane has a similar design as a top-running bridge but requires less headroom because the rails are mounted below the runway beams instead of above them.

- Monorail cranes are used for lifting heavy loads. They can be free-standing or suspended from a ceiling and have one end truck that runs along the track.

- A gantry crane is another type of bridge crane; however, it does not use an overhead beam to support its weight like most other types of bridge cranes do. Instead, it uses two legs that come down from the ceiling and rest on the floor. This crane can span a longer distance, up to 100 feet, and has a capacity of up to 25 tons. Read More.

To help you understand what type of bridge crane you need, we’ll go over in depth the common types here.

Single Girder Bridge Cranes

Single girder bridge cranes offer a cost-effective and efficient lifting solution for applications with lighter loads and lower speeds. A single girder crane is also more compact than other types of bridge cranes, which can be beneficial in facilities with limited building height or floor space.

Another advantage of these systems is that they only require one bridge beam, which results in less dead weight and makes them more adaptable to lighter runway technologies and integration with the existing building support structure.

Benefits of a single girder design:

- For light to medium-duty cranes, it’s the most cost-effective option.

- A better hook approach for both trolley and bridge travel

- Reduced weight on runway rails/beams means less wear on the beams and end truck wheels

- Ideal for low-headroom environments

Double Girder Bridge Cranes

Double girder bridge cranes offer a more robust solution for applications with heavier loads, higher speeds, and/or longer spans than can be supported by single girder systems. This is because they are designed with two beams — an upper beam and a lower beam — which translates to greater capacity. The girders run parallel to each other, and the trolley travels along both beams.

Benefits of a double girder design:

- For medium-duty to heavy-duty cranes, it’s more cost-effective overall than two single girder cranes.

- Hook height — how much higher the hoist will lift than a single girder — typically 18 to 36 inches more than a single girder.

- There are no restrictions on maximum span or capacity.

- A double girder design may be used to add pathways, maintenance platforms, cabs, magnetic reels, and lights.

Top Running Bridge Crane

A top running overhead crane has a fixed rail or track system installed on the top of each runway beam. This allows the end trucks to carry the bridge and hoist along the top of the runway system.

There are two types of top running cranes — the single girder bridge design and the double girder bridge design. The single girder bridge uses an underhung trolley and hoist, while the double girder design uses a top running trolley and hoist.

The capacity of a top running overhead crane is unrestricted, which means it can carry either small or large capacity loads. A range of capacities may be found in running cranes, which range from 1/4 ton to 100 tons or more. These overhead cranes are supported by the building structure or runway support columns and are perfect for moving large weights.

Benefits of a top running single girder crane include:

- A typical load capacity of 1/4 ton to 20 tons

- Have a typical span of under 65 feet

- Can handle light to medium service

- Deadweight is low

- More overhead space

- The hoist and trolley speed is faster.

- With less material required, you can expect to see a lower cost per production unit and a reduced overall price.

Benefits of a top running double girder crane:

- Because the hoist and trolley can run on top of the two bridge girders, it provides for the greatest hook and lifting height.

- Provides the maximum area of overhead floor room.

- High speed

- Can handle a typical load capacity of 20 to 400 tons

- Typically spans +65 feet

- Handles medium to heavy-duty service

Under-Running

An under-running crane, often known as an “underhung” crane, moves the bridge up and down the runway by rolling on wheels that are supported by the bottom flange of the runway beam. Most often, underhung cranes are built in a single girder form for lighter service and lower-capacity applications. For greater capacities, they can also be constructed in a twin girder style.

An under-running single girder crane employs an under-running hoist and trolley. This travels along the bridge beam’s bottom. A double girder over-running crane may utilize its hoist and trolley on either the top or underside of the bridge beam.

These types of cranes can help you use the space in your facility more efficiently. This is because they are commonly supported by the existing ceiling or roof.

An under-running overhead crane should be used when you have a low headroom situation. This is because they run on wheels that are mounted below the bridge girder allowing for more space between the bridge and the overhead obstruction.

Benefits of an under running overhead crane:

- Has a typical load capacity of 1/4 ton to 15 tons

- The typical span is less than 65 feet

- Can handle light to medium duty service

- If supported by existing ceiling trusses or a roof structure, this design maximizes floor space.

- If no runway support columns are required, the cost of materials is reduced.

Monorails

A monorail crane is a bridge crane with a monorail system that operates above the ground. This allows the load to be moved in a single plane, which is often on a straight path. Monorail cranes are typically lighter than overhead cranes, and they are commonly used for assembly applications.

A monorail crane can help lift and transport large, heavy items with ease. They also provide enough space for operators to move about easily. Monorails are commonly used in a variety of commercial settings including industrial plants, warehouses, automobile showrooms, convention centers, retail stores, and more.

There is a wide range of monorail crane capacities to choose from, making it easy to find the perfect option for your needs.

Benefits of a monorail overhead crane:

- Increased efficiency

- Functionality that is both safe and dependable

- Low operational expenses

- Reduced labor expenses

- Effortless load control

- Switch and transfer sections offer multiple lines and storage

- Lift and drop sections provide elevation changes

Trolleys

Trolleys work with bridge cranes to move the load horizontally. This is done by mounting the trolley onto the crane’s I-beam and then attaching the load to the trolley. The trolley will then move along the beam with the load in tow. There are a few different types of trolleys that can be used depending on your needs. These include:

Electric Trolleys. These trolleys use an electric motor to haul the load horizontally along the bridge girder. They are powered by a battery that is recharged periodically when not in use, or they can be plugged into a power source while in operation.

Hand-Powered Trolleys. If you don’t want to use an electric-powered trolley, you can choose a hand-powered option. This is a good choice if your overhead crane system doesn’t have electricity available or if you prefer to control the movement of the load manually.

Air Trolleys. Air trolleys are used when there’s no power source available for an electric trolley. These trolleys use air pressure to move the load along the bridge girder. They are a good choice for outdoor applications where an electric motor might not be suitable.

Top running and bottom running trolley

A top running trolley is designed to run on the top flange of a girder. The wheels roll along this surface and can either be attached by bolting or welding. This type is used typically in low headroom situations.

A bottom running trolley is designed to run on the bottom flange of a girder. The wheels roll along this surface and are attached by bolting or welding. This type is used typically in high headroom situations where an under-running crane can’t be used.

Benefits of using a trolley with your bridge crane:

- Allows you to move heavy items horizontally with ease

- Eliminates the need for manual labor

- Improves safety, reducing the risk of workplace injuries

Bridge Crane Pros and Cons

When choosing a bridge crane, it is important to consider the pros and cons of each type. Doing so will help you find the best fit for your needs.

Pros:

- Several bridge crane types are available to meet the unique needs of your application. The various designs can help you maximize efficiency and productivity while helping reduce operating costs.

- Top running cranes have advantages over underhung and wall-traveling cranes when there is a need for heavy lifting operations, large spans, or long lifts.

- Top running bridge cranes are supported by the building structure or runway support columns and are perfect for moving heavy weights. This type of crane offers unrestricted capacity and can handle a wide range of applications.

- Overhead bridge cranes are very adaptable and customizable. This means that you can change the way they work to fit your needs. Many cranes have a variety of below-the-hook lifting tools, which are replaced depending on the task. These include spreader bars, c-hooks, weight scales, custom-designed lifting tooling, manipulators, and vacuum lifts.

- With an overhead bridge crane, the operator can set up the load and then step away from danger using a radio or an independent traveling pushbutton station.

- Soft start capabilities, a wide range of speed selections, and various handling tools or rigging make it possible to safely handle loads.

Cons:

- Bridge cranes require more overhead space than other types of overhead/non-mobile cranes, so they may not be suitable for certain facilities. If you have a low headroom situation, an under-running overhead crane is a better option. Under running bridge cranes are supported by wheels that run on the bottom flange of the runway beam. This type of crane should be used when you have a low headroom situation.

- They can be more expensive to purchase and operate than other types of cranes.

- If you have an open span, consider using a gantry crane instead of an overhead bridge crane. A gantry is supported by the floor rather than from above and may be what your facility needs.

- If you need mobility to move your bridge crane throughout the plant for various applications, use a workstation or jib crane instead. A workstation or jib crane can be attached to the floor, ceiling, or wall and provide mobility for your lifting operations.

Contact American Equipment for help deciding on a lifting solution!

Overall, a bridge crane can be a great investment for your business. It is important to consider the unique needs of your facility when selecting the best type of crane for the job.

Not sure which type of bridge crane is best for your lifting needs? Contact American Equipment today! Our experienced crane specialists can help choose the right overhead crane for your heavy lifting application.