It is no surprise that overhead cranes are for lifting material overhead, but there are many different types. It can be confusing to understand the overhead crane types and what they should choose based on their needs. In this article, we will outline the three most common overhead crane types. We’ll also explore what business owners should consider when choosing which type is best for them.

Overhead Crane Types

As any industrial business owner knows, there are many projects that require the use of cranes for overhead lifting and moving. It is important to select the overhead crane that best suits the specific task at hand. This ensures safety and productivity.

Overhead Bridge Crane

The overhead bridge crane is the most common type of overhead crane. It moves back and forth along a track that spans the entire length of the work area. This type of overhead crane can be of use for both heavy and light-duty applications.

Overhead bridge cranes are of use in manufacturing plants, warehouses, and distribution centers. This type of crane is also known as a bridge crane because it spans the entire work area below.

Read More: What is a Bridge Crane?

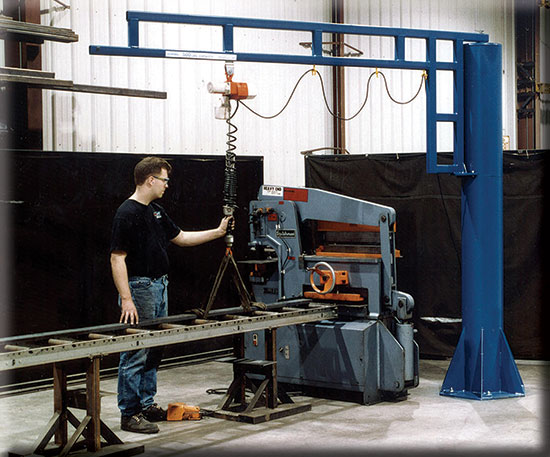

Jib Crane

A jib crane is a type of overhead lifting equipment. It is frequently of use in a smaller work cell space for repetitive and unique lifting operations. Jib cranes are highly flexible, and they may combine with overhead bridge cranes to boost production even further.

Jib cranes are typically quite basic in design, but they can range from 250 pounds to 15 tons in certain situations. Their ergonomic form is very appealing in a manufacturing setting. It may enhance employee productivity, minimize workplace accidents, and improve safety.

Read More: What is a Jib Crane?

Gantry Crane

Gantry cranes are overhead cranes with a single or double girder construction supported by free-standing legs that move on wheels or along a track or rail system. When there is a good reason not to use an overhead runway system or permanently connect it into the building’s support structure, this sort of crane system is frequently of use.

Moreover, gantries are frequently of use for outdoor usage or beneath an existing overhead bridge crane system. Depending on the requirements of usage, length of travel, and load capacities, gantries may run on track, rail, or even directly on the floor.

Overall, gantry cranes are specifically for high-volume lifts. They offer an efficient way to lift or move heavy weights throughout a yard, fabrication shop, or general manufacturing/warehousing environment.

Read More: What is a Gantry Crane?

Workstation Crane

A Workstation Crane is an overhead crane that provides ergonomic means of moving or lifting loads in a smaller workplace. These are lighter-duty systems that lift weights up to 2 tons in capacity. The design is for the repetitive lifting of freight, allowing for increased worker productivity and ease of workflow.

Workstation cranes can be free-standing or ceiling-hung, and they may be top running or under running. These cranes are popular among manufacturing and production businesses because they are flexible, customizable, and expandable through modular design.

Single-girder vs. double-girder

Single and double girder cranes have similar strength and longevity. The primary distinction between the two is in hook height, or how high above the ground a hoist may lift. A double girder crane can accommodate extra hook height. This is because the hoist is on top of the girders rather than beneath them.

This difference is important for businesses that need to lift or move loads over people, machines, or other obstacles. In most cases, a single girder crane can do the job just as well as a double girder overhead crane. However, it is crucial to consult with an overhead crane manufacturer to be sure.

Examples of where a double girder or single girder design may be preferable.

Single Girder – On each side, the girder beam is supported by an end truck. The trolley and hoist are underhung, which means they run on the bridge’s bottom flange. They are also less expensive because of:

- Just one girder is required to move the trolley.

- Lower freight expenses

- Installation is faster.

- Use of a simpler hoist and trolley design

The single girder crane is ideal for light-duty loads (up to 25 tons) and is easy to handle. Moreover, it is easy and inexpensive to install, making it a popular option for small businesses.

Double Girder – There are two girder beams that make up the bridge, and they are both supported by an end truck on each side. On top of the bridge girders, a rail supports the trolley and hoist. For heavier-duty applications where the crane must lift more than 15 tons or the span is greater than 65 feet, double girder overhead cranes offer the best performance.

Double girder overhead cranes are also a smart choice when using a top running hoist. This is because they provide better stability and balance, which increases safety. Moreover, double-girder overhead bridges have more clearance for longer trolley travel. That way they can accommodate heavier loads with less stress on the bridge itself.

When the crane needs modifications with walkways, cabs, magnet cable reels, or other specialized equipment, twin girder cranes are the best solution. They can also give greater lifting height because the hoist is not located beneath the beam on a top running design.

Top running vs under running.

When it comes to distinguishing between bridge cranes, you should think about whether you need a top-running or under-running crane.

Bridges on a top running crane have support from the runway beams and travel along the top of them. The bridges on an underrunning or underhung crane are supported by the bottom of the runway beams. They move along the bottom of the lower beam flange.

Top running cranes – The capacity of these cranes is unrestricted—they can be manufactured to operate from tiny capacities to huge ones. The wheels of each bridge turn on a rail that runs along the top of the runway instead of the runway’s bottom flange. These cranes are supported by the building’s structure or runway support columns, or sister columns, and can lift enormous weights.

Under running cranes – The name “underhung” comes from the fact that the crane wheels are secure by the bottom flange of the crane runway beams, which serve as the crane rail. Because the ceiling trusses or roof struck support them, these cranes may help you to use your facility’s floor space for the production and storage of material. They can either stand on an existing support structure (if available) or be constructed around a new one.

How to Choose the Right Overhead Crane for Your Needs

When you need overhead cranes, it is important to know what type suits your specific application and budget. By understanding the different overhead crane types and their benefits, you can make an informed decision about what is best for your needs.

Consider the following when choosing between the many types of overhead cranes:

- Number of cranes required

- Crane capacity

- Hoist capacity

- Number of lifts performed each hour

- Span

- Hook Height

- Runways and support structures have already been built.

- Operating conditions

There are many different overhead crane types on the market. Therefore, business owners need to understand what their specific needs are to make an informed decision about which type of overhead crane to buy.

American Equipment designs overhead cranes for every application.

We will work with you one-on-one to understand your overhead crane needs and provide a custom solution. Contact us for all your overhead crane needs in the Western United States.